Services Offered

Our Services

Why Test?

- Early Detection – Find leaks before they cause costly structural damage.

- Quality Assurance – Verify membrane integrity after installation.

- Warranty Compliance – Satisfy manufacturer and project specifications.

- Non-Destructive – Test without damaging finished surfaces.

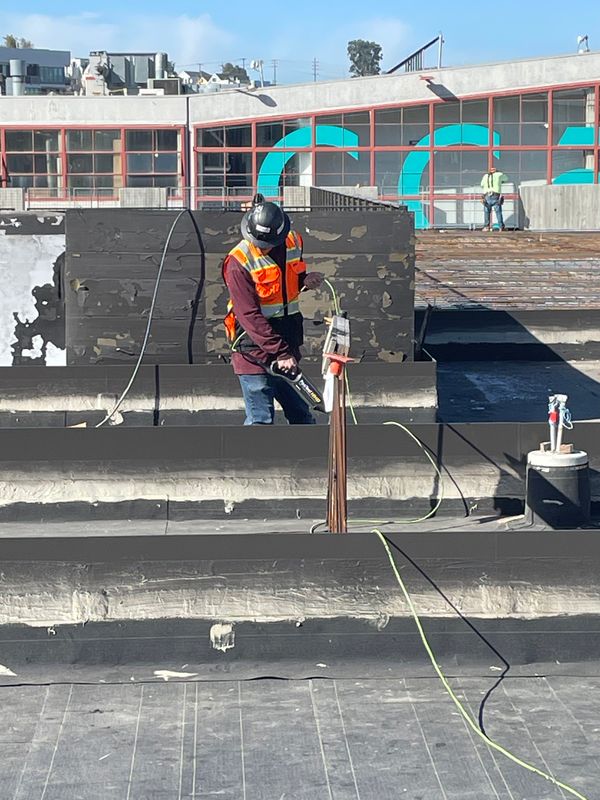

Our ELD Testing Process

- Conductive Layer Verification – Ensure proper substrate or conductive medium is in place.

- Equipment Calibration – Instruments are properly calibrated and set to appropriate sensitivity levels.

- Testing of Membrane – Use low-voltage and/or high-voltage electronic testing

- Pinpoint Location – Mark exact location of breaches for repair.

- Retesting Of Membrane – Retest repaired breaches as needed.

- Documentation – Provide a detailed report with location maps, photos, and pass or fail status of area tested.

Key Benefits to Our Services

- Fully ASTM Compliant

- Experienced technicians with specialized training

- Suitable for exposed and covered membranes

- Works with Hot Rubberized Asphalt, PVC, TPO, Modified Bitumen, and other non-conductive membranes and waterproofing coatings.

Why Choose Us?

- Independent Third-Party Validation – Unbiased verification that protects owners, designers, and contractors

- Risk & Liability Reduction – Documented testing helps defend against future claims and disputes

- Efficient & Reliable Scheduling – Performed at optimal project milestones to avoid delays and rework

- Clear, Actionable Reporting – Precise findings that streamline repairs, approvals, and closeout